Views: 0 Author: Site Editor Publish Time: 2025-10-31 Origin: Site

The automotive industry is undergoing a seismic shift toward electrification, lightweighting, and enhanced user experience. In this transformation, material science plays a starring role. Automotive TPE pellets from Shandong Trifon are engineered to meet these new demands, replacing heavier, more expensive, and less versatile materials in critical applications.

Lightweighting: Every gram saved extends the range of electric vehicles (EVs) and improves the fuel efficiency of internal combustion engine (ICE) cars. TPEs are lightweight yet durable.

Aesthetic & Haptic Enhancement: The cabin is becoming a "living space." TPEs provide the soft-touch, premium feel that modern consumers expect on surfaces like dashboards, armrests, and controls.

Durability & Performance: Automotive components must withstand extreme temperatures, UV exposure, chemicals, and constant wear. Our TPE compounds are formulated for this harsh environment.

Design Integration & Cost Reduction: TPEs allow for complex part consolidation and overmolding, reducing assembly steps and overall production costs.

1. Interior Comfort & Convenience

Application Examples:

Soft-Touch Dashboard & Door Panel Skins: Replacing harder PVC with grained, low-gloss TPEs for a premium look and feel.

Armrests and Headrests: Providing comfortable, durable padding.

Knee Bolsters and Trim Components: Enhancing safety and comfort while reducing noise (NVH).

Window and Sealing Systems: Offering excellent weather-stripping properties and long-term compression set resistance.

Trifon's Material Solution: We offer low-VOC (Volatile Organic Compound), fogging-resistant, and UV-stabilized TPE grades specifically for interior applications.

2. Exterior Durability & Function

Application Examples:

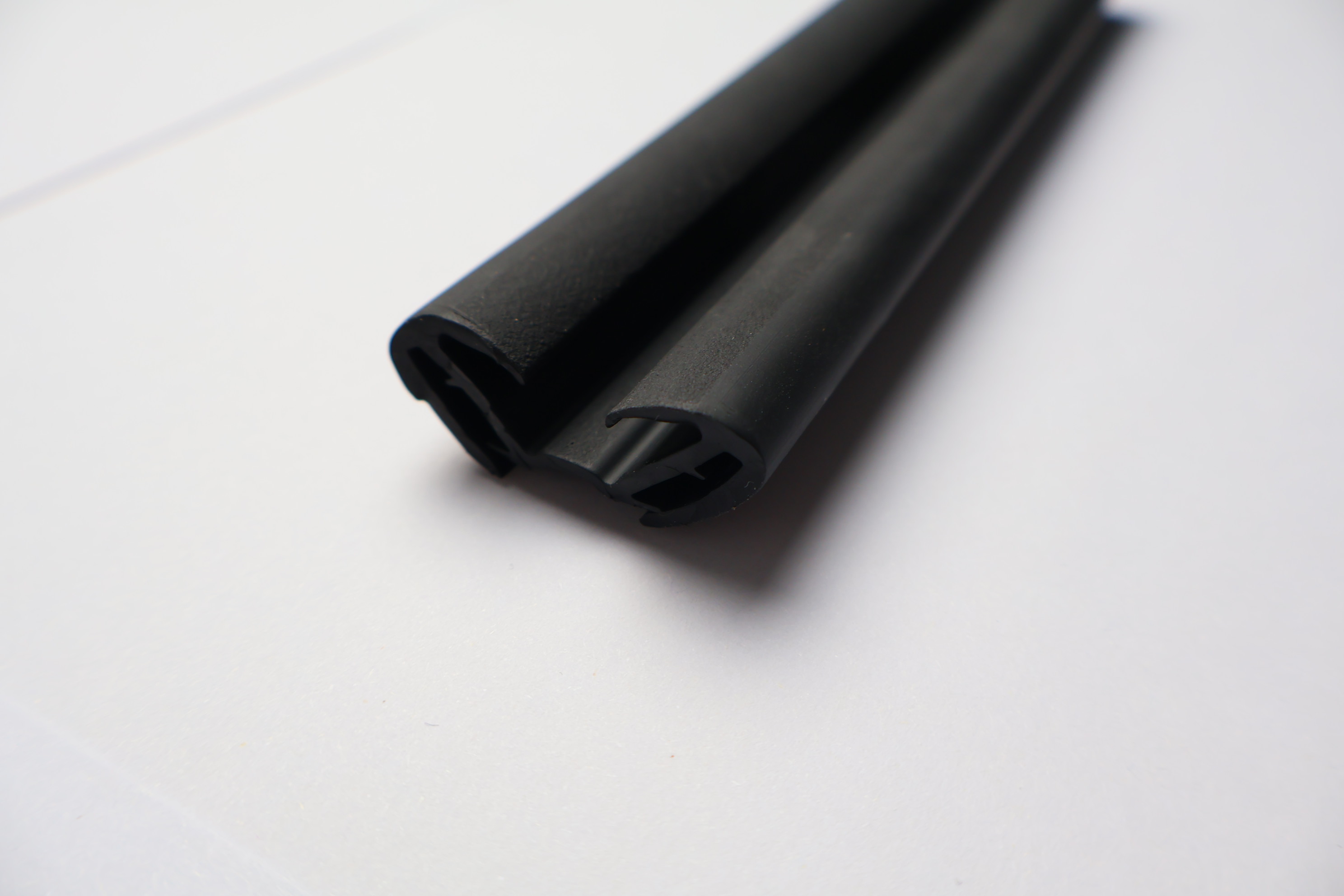

Weather Seals and Gaskets: For doors, windows, and trunks, providing a tight seal against moisture and noise.

Stone & Abrasion Guards: Protecting sensitive body areas.

Grille Components and Badges: Offering design flexibility and paintability.

Trifon's Material Solution: Our exterior-grade TPE pellets possess excellent weatherability, ozone resistance, and a wide service temperature range (-40°C to 135°C).

3. Under-the-Hood & Powertrain

Application Examples:

Air Ducts and Intake Hoses: Requiring heat resistance and flexibility.

Cable Jacketing and Grommets: Demanding oil and chemical resistance.

Battery Cushioning Pads for EVs: Needing flame-retardant properties and electrical insulation.

Trifon's Material Solution: We develop specialized TPE compounds with enhanced heat aging performance (withstanding up to 150°C), resistance to engine fluids, and flame-retardant (FR) properties meeting automotive standards.

The automotive industry cannot tolerate failure. A key pain point is supplier reliability and material consistency.

Pain Point: Risk of part failure, recall, and brand damage due to sub-standard materials.

Our Solution:

IATF 16949 Compliance: Our manufacturing processes are aligned with the global quality management standard for the automotive industry.

Full Traceability & Lot-to-Lot Consistency: We provide comprehensive batch documentation, ensuring every shipment meets your strict PPAP (Production Part Approval Process) requirements.

Global Material Data System (IMDS) Support: We provide accurate IMDS data for easy submission to OEMs, ensuring compliance with end-of-life vehicle regulations.

Q1: Can your TPE pellets be overmolded onto PP substrates for interior trim?

A: Yes, this is one of our core specialties. We offer a range of TPEs with excellent adhesion to Polypropylene (PP), the most common plastic used in automotive interiors, enabling seamless and durable overmolded parts.

Q2: Do you offer TPEs that meet OEM-specific color and gloss standards?

A: Absolutely. Our color matching capabilities are precise, and we can formulate TPE pellets to meet any OEM's specific color, gloss (e.g., low-gloss for anti-reflective surfaces), and texture requirements.

Q3: How do your TPEs for EVs differ from those for traditional vehicles?

A: For EVs, we focus on specialized grades for battery systems (flame retardancy, insulation), quieter cabins (enhanced NVH damping), and materials that can withstand different thermal management cycles.

Q4: What is your lead time for a new automotive project requiring PPAP?

A: We have a structured process for new projects. From sample development and testing to full PPAP submission, the typical timeline is 8-12 weeks, depending on the complexity of the compound and testing required. We work closely with you to meet your program deadlines.

As the automotive landscape evolves, the materials used must be smarter, safer, and more sustainable. Shandong Trifon is committed to being the innovation partner that global automotive suppliers trust to deliver high-performance, reliable TPE pellet solutions.

Accelerate your next automotive project. Reach out to our automotive materials team for a technical consultation and access our portfolio of proven TPE compounds.