Views: 0 Author: Site Editor Publish Time: 2025-10-27 Origin: Site

Meta Description: Partner with Shandong Trifon, a leading TPE pellets manufacturer. We explore material selection, customization, and how our ISO-certified TPE compounds solve manufacturing challenges for superior, sustainable products.

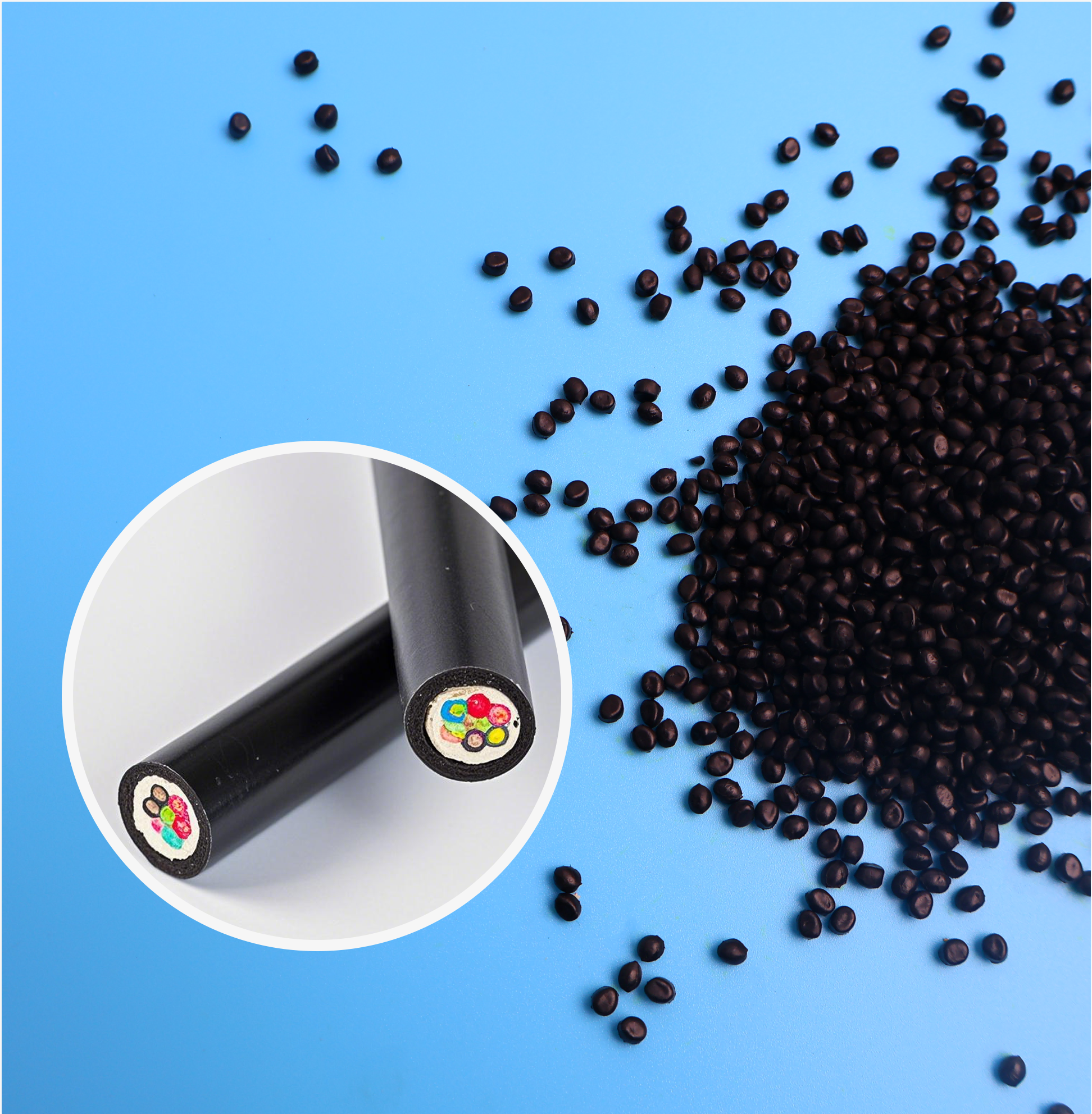

In the competitive landscape of product manufacturing, the materials you choose are as critical as the design itself. Thermoplastic Elastomer (TPE) pellets have emerged as a cornerstone of innovation, offering unparalleled flexibility, durability, and processing ease. However, not all TPE compounds are created equal. The difference between a product that thrives in the market and one that fails often lies in the expertise of your TPE pellets manufacturer.

Selecting a supplier is more than a procurement decision; it's a strategic partnership. This guide will navigate the key considerations, from material properties to supply chain reliability, helping you understand why Shandong Trifon New Material Technology Co., Ltd. is the trusted choice for global industries seeking quality, consistency, and innovation.

Thermoplastic Elastomers are a class of polymers that combine the processing advantages of rigid thermoplastics with the elastic properties of vulcanized rubber. This hybrid nature makes TPE granules incredibly versatile.

Key Characteristics include:

Elasticity and Soft-Touch: Provides a comfortable, grippy feel for consumer products, tools, and automotive interiors.

Recyclability: Unlike thermoset rubbers, TPEs can be melted and reprocessed, reducing waste and supporting sustainability goals.

Ease of Processing: They can be efficiently processed using standard plastic equipment like injection molding, extrusion, and blow molding, leading to faster production cycles and lower energy consumption compared to rubber.

Excellent Adhesion: Certain TPE compounds are engineered to bond securely with substrates like PP, PE, ABS, and PA, enabling complex overmolding applications.

Manufacturers often face significant challenges when sourcing TPE materials. A proficient manufacturer doesn't just supply pellets; it provides solutions to these core pain points.

1. Pain Point: Inconsistent Material Quality and Performance

The Risk: Batch-to-batch variations in hardness, color, or flow properties can lead to production line stoppages, high rejection rates, and final products that fail quality checks.

Trifon's Solution: We implement a rigorous Quality Management System certified to ISO 9001:2015. Our state-of-the-art production facility features advanced compounding technology and an in-house laboratory for continuous raw material inspection, in-process monitoring, and final product testing. This ensures every bag of TPE pellets meets the exact specifications you ordered.

2. Pain Point: Limited Customization Capabilities

The Risk: An "off-the-shelf" TPE compound may not meet your specific requirements for UV resistance, flame retardancy, food-contact compliance, or adhesion, forcing you to compromise on product design.

Trifon's Solution: Our core strength lies in custom TPE compounds. Our R&D team works directly with you to develop a tailored material solution. We can adjust:

Hardness: From ultra-soft gel-like materials (as low as 5 Shore OO) to semi-rigid grades (up to 60 Shore D).

Additives: Incorporate color masterbatches, UV stabilizers, anti-oxidants, and flame retardants to meet industry-specific standards.

Special Properties: Engineer materials for medical-grade (ISO 10993), food-contact (FDA, LFGB), and automotive specifications.

3. Pain Point: Unreliable Supply and Logistics

The Risk: Production delays due to late material shipments can be catastrophic, leading to missed deadlines and lost revenue.

Trifon's Solution: Located in Shandong, China, a major industrial and logistics hub, we guarantee reliable and timely global shipments. Our robust supply chain management and strategic partnerships with logistics providers ensure your production line never stops. We offer flexible packaging options, from 25kg bags to 1-ton jumbo bags, all on pallets for safe transit.

4. Pain Point: Inadequate Technical and Customer Support

The Risk: Without expert guidance, you may select an unsuitable material, leading to processing difficulties and product failure.

Trifon's Solution: We assign a dedicated technical support manager to your account. From the initial inquiry to mass production, we provide comprehensive Technical Data Sheets (TDS), Material Safety Data Sheets (MSDS), and processing guidelines. Our team is available to troubleshoot and optimize your molding parameters for maximum efficiency.

At Shandong Trifon, we go beyond being a supplier. We are your innovation partner. Our commitment is reflected in our core competencies:

Advanced R&D Facility: Continuous investment in research allows us to pioneer new TPE formulations, including bio-based and biodegradable TPEs, positioning you at the forefront of market trends.

Stringent Quality Control: Every production batch undergoes tests for hardness, tensile strength, elongation, tear resistance, and color consistency.

Global Compliance: Our materials are developed to comply with international standards like REACH, RoHS, and FDA,

ensuring your products can be sold in markets across North America, Europe, and Asia.

Proven Industry Expertise: Our TPE pellets are trusted in diverse sectors, including:

Automotive: Seals, gaskets, interior trim, and anti-slip mats.

Consumer Products: Tool handles, appliance grips, and footwear.

Healthcare: Respirator masks, syringe seals, and medical device housings.

Wire & Cable: Jacketing and insulation materials.

Q1: What is the typical lead time for orders?

A: For standard grades, we maintain stock for quick dispatch. For custom compounds, the lead time is typically 15-25 days after final formula confirmation, depending on the order quantity.

Q2: Can your TPE pellets be overmolded onto other plastics?

A: Absolutely. We specialize in developing TPEs with excellent adhesion to a wide range of substrates, including Polypropylene (PP), Polyethylene (PE), and ABS. We provide adhesion test reports to validate performance.

Q3: Do you offer eco-friendly or sustainable TPE options?

A: Yes. We offer a range of sustainable solutions, including TPEs with recycled content, bio-based TPEs derived from renewable resources, and compounds designed for easier recycling.

Q4: What is the minimum order quantity (MOQ) for a custom TPE compound?

A: Our standard MOQ for a new custom compound is 1 metric ton. We are flexible and can discuss lower quantities for initial sampling and testing phases to support your R&D.

Q5: How do you ensure color consistency?

A: We use computer-controlled color dosing systems and spectrophotometers to measure color accuracy against standard values (e.g., Pantone, RAL) for every batch, ensuring perfect color match.

Q6: Are your TPE pellets suitable for food-contact applications?

A: Yes, we have specific TPE grades that are compliant with FDA (U.S.) and LFGB (EU) regulations for food-contact surfaces. Please inquire about our specific food-grade TDS.

Choosing the right TPE partner is a decision that impacts your product quality, manufacturing efficiency, and ultimately, your brand reputation. Shandong Trifon New Material Technology Co., Ltd. is committed to providing more than just materials; we deliver reliable, high-performance solutions backed by scientific expertise and unwavering customer support.

Ready to discuss your specific project requirements? Contact our TPE experts today for a free consultation and sample testing. Let us help you turn your innovative product ideas into reality.