Views: 0 Author: Site Editor Publish Time: 2025-09-28 Origin: Site

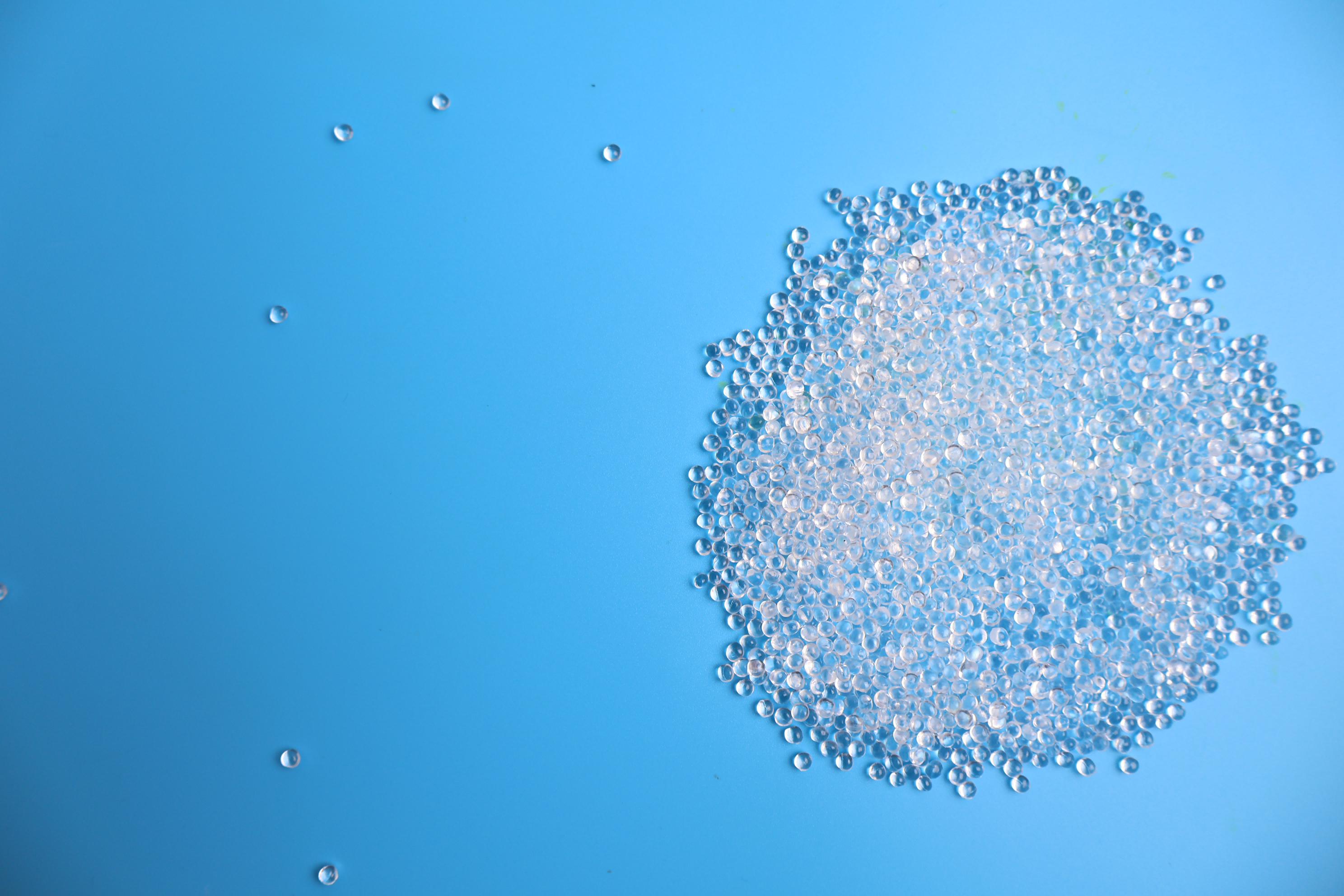

In today’s competitive manufacturing world, product designers and engineers are increasingly turning to thermoplastic elastomers (TPE pellets) as their preferred material. Flexible, durable, and recyclable, TPE has become a vital alternative to traditional rubber and plastics in industries ranging from automotive to medical, consumer goods, and construction.

As global demand grows, sourcing TPE pellets from China has become a smart choice for manufacturers seeking high-quality materials at competitive prices. Among China’s TPE suppliers, Shandong Terrifon New Materials Co., Ltd. stands out with more than 40 years of R&D experience, advanced production facilities, and a commitment to sustainability.

This article will guide you through what TPE pellets are, why they matter, and why Terrifon is your ideal partner for long-term cooperation.

Thermoplastic elastomers (TPE) are a unique class of polymers that combine the flexibility of rubber with the easy processability of thermoplastics. Unlike traditional rubber, which requires vulcanization, TPE can be melted and remolded multiple times—making it cost-effective and environmentally friendly.

Key characteristics of TPE pellets include:

Excellent flexibility and elasticity

Wide hardness range (Shore A to Shore D)

Resistance to chemicals, UV, and weathering

Recyclability and reusability

Easy processing with injection molding, extrusion, and blow molding

This combination of properties makes TPE a go-to solution for industries looking to balance performance, cost, and environmental responsibility.

China has rapidly grown into a global powerhouse in advanced polymer materials, and TPE production is no exception. There are several reasons why manufacturers worldwide prefer Chinese suppliers:

Cost-effectiveness: Competitive pricing without compromising quality.

High production capacity: Scalable supply chains ensure timely delivery for both small and bulk orders.

Advanced technology: Continuous R&D in polymer science makes China a leader in innovative TPE solutions.

Global compliance: Many Chinese TPE suppliers, including Terrifon, adhere to RoHS, REACH, and FDA standards.

According to Grand View Research, the global TPE market size was valued at over USD 20 billion in 2023 and is expected to grow at a CAGR of more than 6% by 2030.

Shandong Terrifon New Materials Co., Ltd. is a professional TPE pellets manufacturer with decades of expertise. Our factory is equipped with advanced extrusion lines, strict quality control systems, and an R&D team dedicated to continuous innovation.

Why choose Terrifon?

✔ 40+ years of polymer R&D experience

✔ Flexible customization for hardness, color, and special performance

✔ Professional technical support and after-sales service

✔ Strong presence in global markets, including the Middle East, Europe, and North America

By focusing on TPE production, Terrifon ensures clients receive not just material supply, but also tailored solutions for their specific applications.

Used in seals, gaskets, grips, and interior trims

Replaces PVC and rubber with lightweight, eco-friendly solutions

Offers high durability, impact resistance, and anti-slip performance

Biocompatibility and non-toxicity make TPE ideal for medical tubing, seals, and grips

Sterilization resistance ensures safe usage in healthcare environments

Provides soft-touch surfaces for grips, cases, and handles

Anti-slip and anti-aging properties enhance product quality

UV resistance and weatherability make TPE perfect for outdoor applications

Used in roofing, sealing, and photovoltaic brackets

Sustainability – 100% recyclable, reducing waste and promoting eco-friendly production

Cost savings – Lower processing costs compared to thermoset rubber

Design flexibility – Wide hardness and color options for diverse applications

Compliance – Certified for RoHS, REACH, and FDA standards

Like any material, TPE comes with certain challenges:

Cost fluctuations: Global raw material prices may affect production costs.

→ Terrifon offers stable supply contracts to minimize risks.

Processing requirements: TPE requires optimized molding parameters.

→ Our technical support helps clients adjust processing for best results.

Performance balance: Softness vs. durability can be tricky to achieve.

→ Terrifon’s R&D team develops customized formulas for each application.

By addressing these challenges, we ensure our clients enjoy hassle-free material sourcing.

Automotive Client (Middle East): Switched from PVC to TPE for interior trims, achieving 20% cost savings and improved sustainability.

Electronics Client (Europe): Used TPE for grips and cases, boosting product lifespan and reducing defects by 15%.

Construction Client (Asia): Adopted UV-resistant TPE for roofing, extending durability under desert conditions.

MarketsandMarkets predicts the automotive industry will remain the largest consumer of TPE, driven by lightweight and eco-friendly trends.

Soft-touch grips → Shore A 20–50

Structural parts → Shore D 40–70

Outdoor products → UV-resistant, weatherproof TPE

Medical devices → FDA-compliant, biocompatible TPE

EU markets → REACH-certified

Food-grade → FDA-certified

Q1: Are TPE pellets recyclable?

Yes, TPE can be melted and reused multiple times, making it highly sustainable.

Q2: What’s the difference between TPE, TPU, and TPV?

TPE: General-purpose, flexible, recyclable

TPU: High abrasion resistance, tougher than TPE

TPV: Excellent heat resistance and durability

Q3: Can TPE replace silicone in medical products?

Yes, in many cases TPE offers a cost-effective, biocompatible alternative to silicone.

Q4: What is the MOQ (minimum order quantity) for TPE pellets orders from Terrifon?

We offer flexible MOQs depending on project requirements—contact us for details.

Q5: How fast is shipping to the Middle East / Europe / America?

Standard delivery takes 2–4 weeks depending on location and order size.

TPE pellets are shaping the future of global manufacturing with their flexibility, durability, and sustainability. As industries worldwide shift toward eco-friendly solutions, TPE continues to gain importance across automotive, medical, consumer goods, and construction sectors.

With decades of expertise and a customer-first approach, Shandong Terrifon New Materials Co., Ltd. is your trusted partner for high-quality TPE pellets. Whether you need standard grades or customized solutions, our team is ready to support your success.

Contact us today for samples, technical support, or a free quotation. Let’s build a sustainable future together with TPE!